|

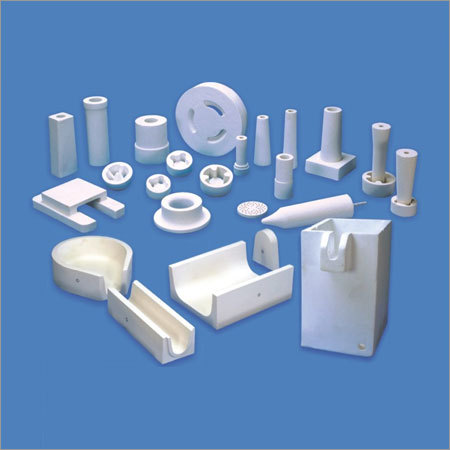

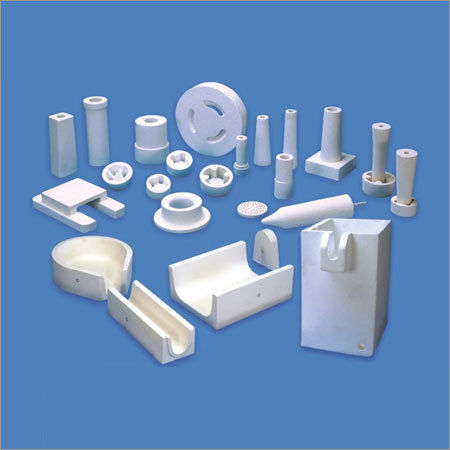

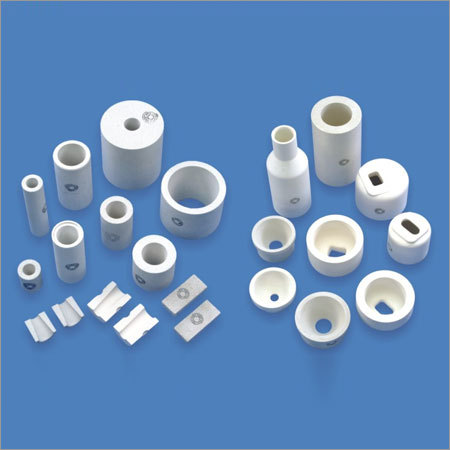

LPDC And GDC Die Coats

250 INR/Piece

Product Details:

- Product Type Mineral Refractories

- Dimensional Stability Reversible

- Color White

- Click to View more

X

LPDC And GDC Die Coats Price And Quantity

- 250 Piece

- 250 INR/Piece

LPDC And GDC Die Coats Product Specifications

- White

- Reversible

- Mineral Refractories

LPDC And GDC Die Coats Trade Information

- 7 Days

Enter Buying Requirement Details

Other Products in 'Aluminium Refractories ' category

|

CERAFLUX INDIA PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |